Troubleshooting Rotating Machine Components

- SkillCat Team

- Mar 28, 2025

- 5 min read

Mechanical Troubleshooting: Chapter 3

Troubleshooting Rotating Machine Components

In this module, we will learn about the failures of rotating components of a machine. We’ll also learn about how to troubleshoot these failures. Skip to quiz!

Rotating Machine Components

Recall that a mechanical system consists of stationary and moving components.

Some of the rotating components that are part of a mechanical system are:

Couplings, and

Bearings.

Let’s look at each of them.

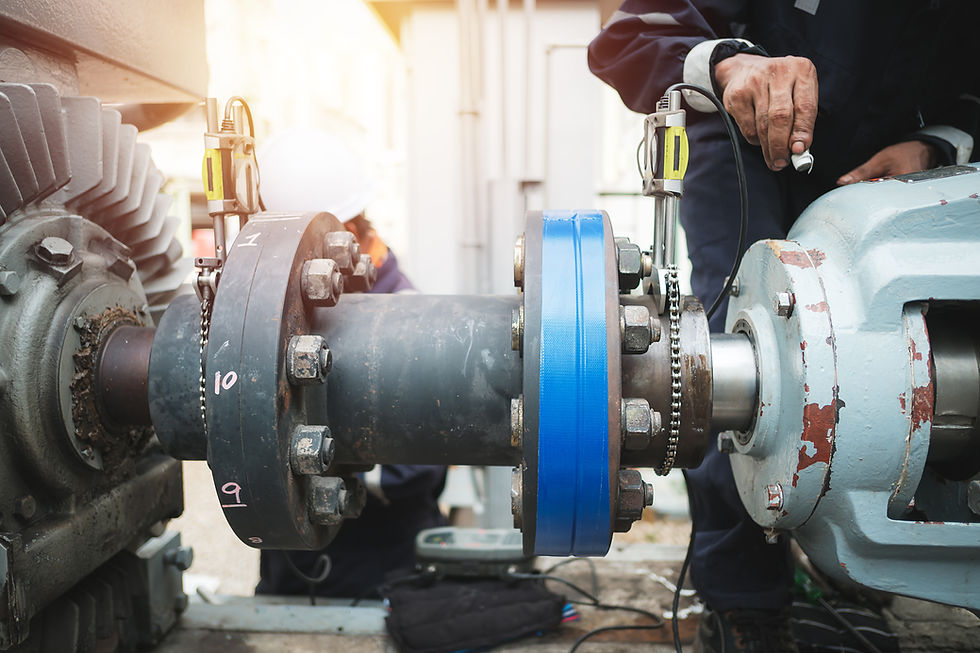

Couplings

A coupling is a device used to connect two shafts. A coupling permits some degree of misalignment between two shafts that are connected.

A coupling is classified into different types depending on the shaft alignment. A rigid coupling is used to connect two shafts that are perfectly aligned. In comparison, a flexible coupling is used to connect two shafts with lateral and angular misalignment.

Some external signs that indicate potential coupling failure include:

Abnormal noises, like screeching, squealing, or chattering,

Excessive vibrations or wobbles, and

Failed seals indicated by lubricant leakage.

Some of the prominent causes for coupling failure include:

Selecting the wrong coupling,

Misalignment, and

Installation error.

Let’s discuss each of them in detail.

Considering that there is more than one type of coupling, proper coupling selection is essential. Improper selection of a coupling can lead to coupling failure.

For example, a universal coupling is used when two shafts axis intersects at a slight angle. In comparison, an Oldham coupling is used where two shafts have a lateral misalignment.

Misalignment of a coupling beyond its specifications introduces the possibility of accelerated wear. Excessive misalignment between joined shafts is one of the most common reasons for coupling failure.

When misalignment exists beyond the specifications of a coupling’s manufacturer, we should rectify it with shaft realignment. Then we need to select the appropriate coupling for the application.

After selecting the appropriate coupling for our application, we need to install it correctly. We need to follow coupling installation instructions to avoid installation failure. Far too many times, a coupling is installed without knowing manufacturer specifications, leading to premature failure.

Some of the primary coupling installation instructions might include:

Prepare the coupling and shafts before installation,

Clean mating parts and oil shafts lightly, and

Check to ensure that any misalignment between shafts is within the coupling's ratings.

We need to ensure the proper alignment of a coupling during installation. Always refer to the specific manufacturer's instructions when performing a coupling installation. This reduces the possibility of failure.

Bearings

Bearings are mechanical assemblies that consist of rolling elements and usually inner and outer races. Bearings support and guide components that rotate relative to one another.

There are many reasons why bearing failure may occur. Some of the most common are:

Improper lubrication,

Contamination,

Misalignment, and

Poor-fitting.

Let’s look at each of them in detail.

The majority of bearing failures occur because of lubrication failure. If a bearing has been exposed to excessive temperatures, then it can cause the lubricant to degrade. This will lead to the failure of the bearing.

Contamination of lubricants is another common cause of bearing failure. Contamination is caused by foreign substances getting into bearing lubricants. These include dirt, abrasive grit, dust, steel chips from contaminated work areas, and dirty hands or tools.

While some bearings can handle minor misalignment between a shaft and bearing housing, not all can. Typical causes of misalignment include:

Bent shafts,

Contaminated components, and

Improperly positioned shafts and locking nuts.

Recall that misalignment of a shaft can cause vibrations. This can lead to uneven load distribution. If we do not fix the misalignment, excessive vibration can result in bearing failure.

A bearing needs to be properly mounted to an accurately sized shaft. If a bearing does not fit correctly on a shaft, it can become damaged during installation or while operating. In most instances, bearings should be mounted with a press fit on the shaft.

If a shaft is oversized, it will result in a tight fit. If a shaft is undersized, it will result in a loose fit. Both these fits result in damage to the bearing. Just like a pair of shoes, too tight or too loose can mean an improper or uncomfortable fit.

A bearing can be damaged during the actual installation. Installation damage is easily noticeable. For example, if the bearing is not aligned correctly during installation, it cuts the bearing raceway.

A valve doesn't shut off or leak if a seal is damaged or worn. Recall that seals prevent the fluid used by a machine from leaking into the external environment. If a valve is leaking, then the possible cause of the valve malfunction is a damaged seal.

Installation damage can be avoided by using correct tools and handling procedures during assembly.

We need to use proper tools when handling and installing bearings. Avoid general-purpose tools like hammers and screwdrivers. All components used to mount bearings should also stay clear of contaminants.

If a bearing failure occurs, it is essential to know the best tools to dismount bearings. To remove failed bearing, we use bearing pullers. A puller securely grips the component with specially designed jaws before driving it off the shaft.

There are two types of bearing pullers. These include:

Internal bearing pullers, and

External bearing pullers.

External bearing pullers are used when a bearing is mounted onto a shaft. They have jaws that grip the outer diameter of the bearing.

Internal bearing pullers are used to fit a bearing or component within a small gap, with an opening in the inner diameter. For example, for removing bearing in a gearbox casing, an internal bearing puller is inserted into the inner diameter of the bearing.

If a bearing fails, we need to replace it.

A coupling is a device used to connect two shafts. Some of the more prominent causes for coupling failure include:

Selecting the wrong coupling,

Misalignment, and

Installation error.

Bearings support and guide components that rotate relative to one another. Some of the most common bearing failures are:

Improper lubrication,

Contamination,

Misalignment, and

Poor-fitting.

Question #1: What are the signs of coupling failure? (Select all that apply)

Lubricant leakage

Abnormal noises

Smooth power transmission

Excessive vibrations

Scroll down for the answer...

Answer: Lubricant leakage

Abnormal noises

Excessive vibrations

Some external signs that indicate potential coupling failure include:

Abnormal noises,

Excessive vibrations, and

Failed seals indicated by lubricant leakage.

Question #2: What are the causes of coupling failure? (Select all that apply)

Selecting the wrong coupling

Misalignment

Lubrication

Installation error

Scroll down for the answer...

Answer: Selecting the wrong coupling

Misalignment

Installation error

Some of the prominent causes for coupling failure include:

Selecting the wrong coupling,

Misalignment, and

Installation error.

Question #3: What are the causes of bearing failure? (Select all that apply)

Improper lubrication

Contamination

Failed seals

Poor-fitting

Scroll down for the answer...

Answer: Improper lubrication

Contamination

Poor-fitting

Some of the most common causes of bearing failure are:

Improper lubrication,

Contamination,

Misalignment, and

Poor-fitting.

Question #4: What causes bearing lubrication failure?

Size of bearing

Vibration

Abnormal noise

Excessive temperatures

Scroll down for the answer...

Answer: Excessive temperatures

If a bearing has been exposed to excessive temperatures, then it can cause the lubricant to degrade.

Question #5: A bearing should be mounted with a ________ on the shaft.

Press fit

Tight fit

Abnormal noise

Loose fit

Scroll down for the answer...

Answer: Press fit

In most instances, bearings should be mounted with a press fit on the shaft.

Question #6: What do we use to dismount a bearing from the shaft?

Dial indicator

Grease gun

Bearing puller

Plier

Scroll down for the answer...

Answer: Bearing puller

To remove failed bearing from housing, we use bearing pullers.

Question #7: What are the types of bearing pullers? (Select all that apply)

Internal bearing puller

Nose clip extractor

External bearing puller

Cross head puller

Scroll down for the answer...

Answer: Internal bearing puller

External bearing puller

There are two types of bearing pullers. These include:

Internal bearing pullers, and

External bearing pullers.

Other References: